Delivering complete Hydromining service packages

It’s the process where the product is converted into slurry by applying high-pressure water, then pumped via a slurry pipeline to the desired location. Water is provided from an external pressure source via 40bar rated rubber hoses, with flow and pressure controlled using interchangeable nozzles up to 58mm.

The remote-controlled NPE Hydromining tracked cannon is specialist Hydromining equipment. NPE manufactures this self-propelled equipment for Hydromining and pond cleaning applications.

Why choose Hydromining?

Hydromining offers a superior alternative to loading and hauling material. It’s fast, safe and cost-effective, making it a popular option for many operations and situations in the mining and construction industry.

The team at NPE offer experienced Hydromining services to a range of mining, civil and municipal requirements throughout Australia. NPE provides world-class Hydromining system design, pump and pipeline supply, installation and operation.

Applications:

- Tailings recovery

- Water pond cleaning

- Pit descaling

- Tank and thickener cleaning

Tailings Recovery

NPE’s Hydromining techniques and slurry pumping capabilities provide a cost -ffective and efficient method of removing and transporting tailings to processing plants. This specialist Hydromining method allows the tailings to be re-mined, unlocking potentially significant value for our customers.

Pit Descaling

Hydromining can be utilised as an effective pit de-scaling (rock dislodgement) tool. With specialist high pressure water equipment, we are able to wash debris off the pit walls and help dislodge potential rock fall hazards present in active pits, from a safe distance. Stop the problem, before it becomes one.

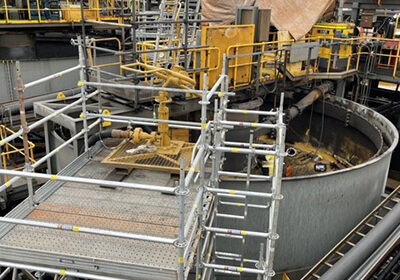

Hydromining Tank and Thickener Cleaning

Hydromining equipment can easily be utilised to wash away material build up in tanks, reservoirs, thickeners and other vessels, to allow for general cleaning and / or inspection / maintenance to be undertaken. To ensure maximum safety, our procedure can be carried out without the requirement for personnel to enter the confined space. By keeping personnel out of these spaces, NPE can minimize risk and associated confined space safety issues. A typical thickener can be cleaned within a 48 hour period making it the ideal solution for shutdowns.

Water Pond Cleaning

Over time, water ponds which are gravity fed become full of tailings, which reduce their storage and surge capacity. These ponds require tailings to be removed periodically, however, because they are typically lined with HDPE (to stop contamination and seepage), and excavation methods can present some risks of liner damage. Hydromining is the perfect solution. It agitates the solids (tailing build-up), pumping it back to the tailings dam. Cost effective and low risk.