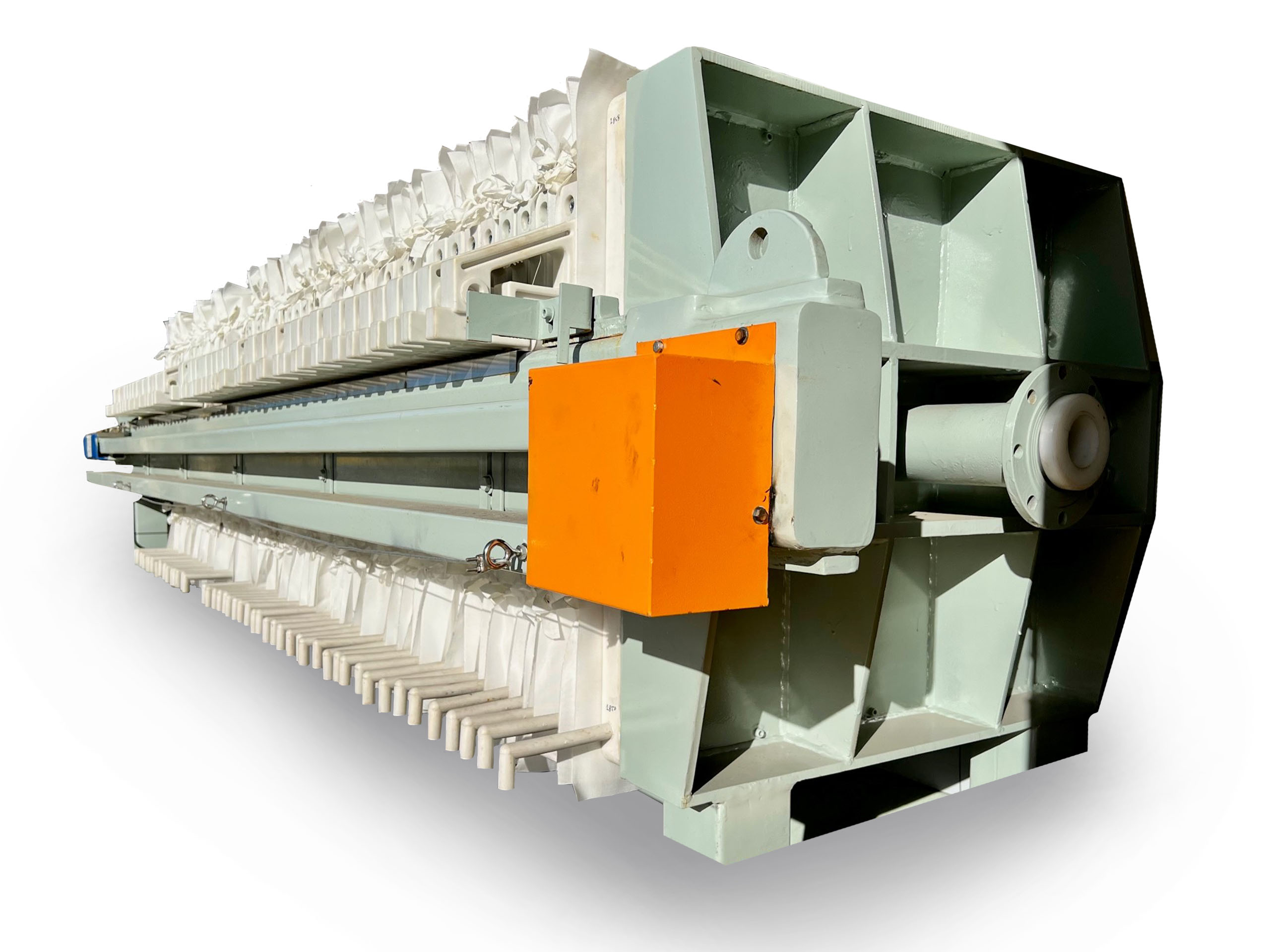

The sludge press is a key component of NPE’s waste water and by-product management systems. The majority of NPE’s water treatment methods produce liquid waste as they remove contaminants from effluent and store them temporarily in a more concentrated form (sludge). Although these volumes are small relative to the volumes of clean water produced, they are tricky to manage on small sites and are expensive to dispose of over the course of a project.

The sludge press maximises the amount of water recovered from waste product, increasing overall system efficiency while significantly reducing the overall volume of sludge and solids that require offsite disposal. Additionally, the sludge press turns “liquid waste” into a friable, spadable cake, which in turn falls under the category of “solid waste”: a form far less expensive to dispose of offsite.

The speed at which sludge can be processed depends heavily on the concentration and nature of the solids within it. Pre-thickened mineral (metal precipitate, fine particle size) sludge can be processed at a rate of about 15 kL every three or four hours, producing approximately 1 m3 of cake. Organic sludge and finely crushed ore (coarse particle size) can produce 1 m3 of cake every 30 – 45 minutes. Dosing of polyelectrolyte to coagulate sludge prior to feed into the press is a requirement in almost all instances.

Process

- Portable and can be safely stacked

- Internal conveying systems

- Minimal rotating or moving parts

- 15 kL of sludge yields 1m3 of caked sludge

- Isolation lanyard and emergency stop button