BA auto prime pump

The BA range of pumps has been designed with a clear focus on reliability, efficiency and durability. Featuring a 100% mechanical priming system, the BA series pumps quickly prime and re-prime, even from dry conditions. The heavy build style of both pump and canopy make the BA range perfect for use in the strenuous contractor market.

World-class performance

The BA range is built to be deployed on the most demanding dewatering and sewage bypassing applications. Using high efficiency pumps and state-of-the-art diesel engines, the pumps offer maximum performance at minimal cost, fully in-sync with the company philosophy of “Lowest cost of ownership”.

BBA E-lift© system

The M10-23X canopy has been fitted with the BBA E-lift© system. By removing the roof panel, the pump and diesel engine as a whole can be removed from the canopy effortlessly allowing easy preventative maintenance on the pump and diesel engine. In addition, as the canopy is not fitted with padding or insulation materials, it can be cleaned quickly using a pressure washer.

KEY FEATURES

- High efficiency pumps minimising fuel consumption

- Corrosion free hot dip galvanized canopy

- Corrosion free composite door panels

- 100% Oil-spill free priming system

- Fully bunded unit eliminating fuel/oil spills at alltimes

Complete package designed & built by BBA Pumps

- Complete in-house design & production

- Over 60 years of experience in the market

- Extensive testing facility in-house

- Contemporary & functional design

- Durable & eco-friendly materials

- Custom builds available

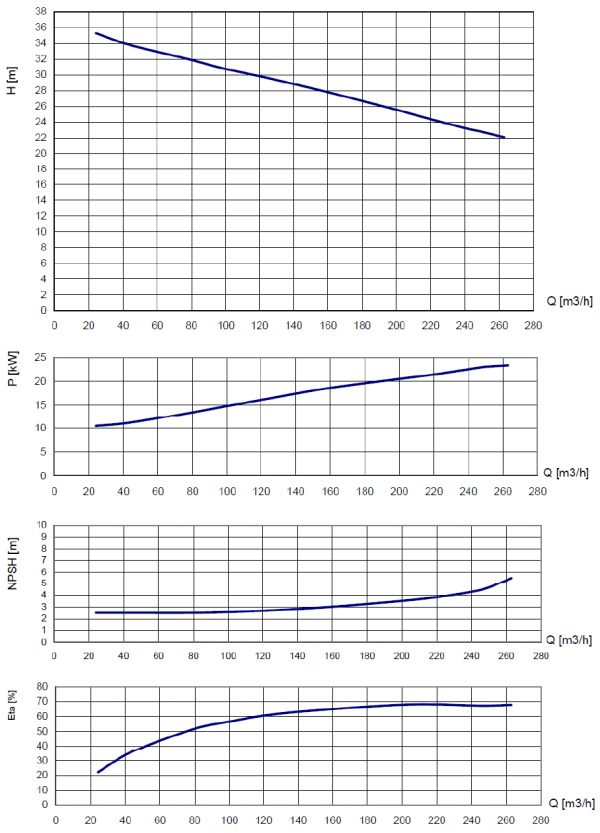

| Pump specifications: | |

|---|---|

| Type | BA100E D265 |

| Max. Flow | 74L/S |

| Max. Pressure | 35 mwc (117 ft.) |

| Connections | DN100 (4ʺ) |

| Solids Handling | 80 mm (3,15ʺ) |

| Impeller Type | Semi-open impeller |

| Priming System | BBA MP50 |

| Engine | Perkins 404D-22 |

| Emission Compliant | Stage IIIA |

| Canopy | M10-23X |

| Sound Level | 64 dB(A) at 10 m |

| Dry Weight | 1600 kg (3527 lbs.) |

| BBA auto prime pump | |

|---|---|

| Pump Casing. | Cast iron GG20 |

| Impeller | Chrome Moly 42CrM04 |

| Self-Cleaning Wear Plate | Chrome Moly 42CrM04 (cutter slots) |

| Pump Shaft | 42CrV6 |

| Shaft Seal | Mechanical seal |

| Seal Faces | Tung/Sic |

| Seal Rubber | Viton |

| BBA priming system | |

|---|---|

| Pump Type | BBA MP50 Diaphragm pump |

| Air Handling Capacity | 50 m3/h (30 CFM) |

| Max. Vacuum | 8.5 m (29 inHg) |

| Drive | Toothed belt (continuous drive) |

| Float Box | Aluminium |

| Non Return Valve | Cast iron GG25 |

| Check Valve Disc | Buna-N |

| Engine | |

|---|---|

| Engine Brand | Perkins |

| Engine Type | 404D-22 |

| Flywheel Power | 26 kW (35 Hp) |

| Max. Engine Speed | 1500 – 1800 RPM |

| Fuel consumption | 243 g/kWh |

| Displacement | 2.2 l |

| Number of Cylinders | 4 |

| Cooling System | Water cooled |

| Emission Level | Stage IIIA – Tier 4i equivalent |

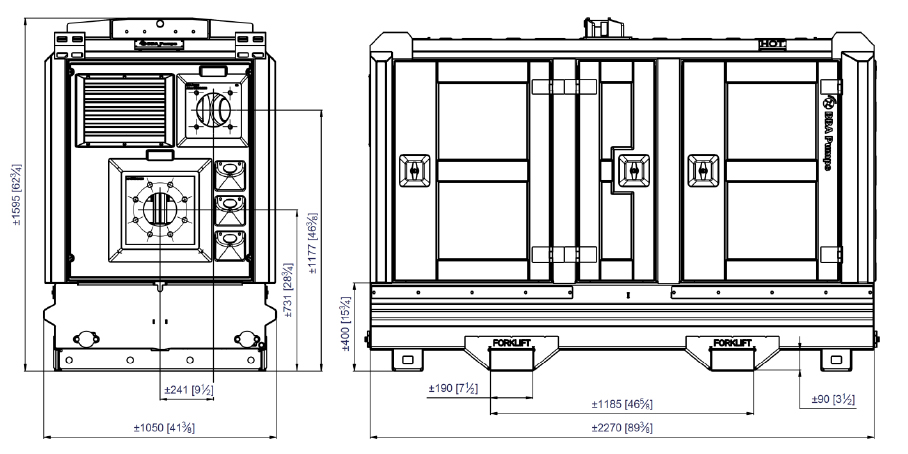

| BBA sound attenuating canopy | |

|---|---|

| Canopy Type | M10-23X |

| Dimensions L x W x H | 2270 x 1050 x 1595 mm |

| Dimensions L x W x H | 89.4 x 41.3 x 62.8 inch |

| Basic Frame | Hot dip galvanized |

| Doors | 6 Lockable Composite Doors |

| Fuel Tank | PE net 300 liters (80 US gallons) |

| Fuel Tank Autonomy | 40 hours (at 1800 rpm BEP) |

| Fuel Tank Cap | 100 mm (4 inch) |

| Forklift Pockets | Fitted with 2 forklift pockets |

| Lifting Point | Fitted with single lifting point |

| Stackable | Canopy is stackable |

| Exhaust System | Fully integrated in canopy |

| Additional | Fitted with oil-water separator |

| Connections | Please consult “auxiliary items” in overleaf |

| Documentation Box | BBA user manual and warranty book |